Mill (grinding) Wikipedia

Ball mill A typical type of ... However, the smaller the rods, the larger is the total surface area and hence, the greater the grinding efficiency. Autogenous mill

WhatsApp)

WhatsApp)

Ball mill A typical type of ... However, the smaller the rods, the larger is the total surface area and hence, the greater the grinding efficiency. Autogenous mill

What is the effect of low ball % full on grinding efficiency?One of our clients is thinking of the future and has bought a ball mill that will be the right size ...

ACHIEVEMENT OF HIGH ENERGY EFFICIENCY IN GRINDING MILLS AT ... • The Bond ball mill work ... Achievement of High Energy Efficiency in Grinding Mills at ...

Cement grinding Vertical roller mills versus ball mills ... The grinding efficiency of the vertical ... to the ball mill system and has increased its share of the ...

Addition of pebbles to a ballmill to improve grinding efficiency S Nkwanyana and B Loveday (1) PRESENTED AT COMMINUTION ''16, MINERALS ENGINEERING INTERNATIONAL ...

Supply professional ball mill equipments including ball mill, grinding mill, wet ball mill, dry ball mill, ball milling, cement ball mill, ball mill machine Jiangxi ...

Grinding Efficiency Ball Mill, Wholesale Various High Quality Grinding Efficiency Ball Mill Products from Global Grinding Efficiency Ball Mill Suppliers and Grinding ...

Factors Affecting the Efficiency of Ball Mill College Essays ... Ball mill is the key equipment for grinding after the crush process, and it is widely used in the ...

Mar 08, 2013· calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill.

A new presentation of this kind of cement and how to configure the ball mill. Protected by. Advertise with us. ... The Cement Grinding Office. Our reference list.

Maximize your grinding efficiency Grinding media solutions ... • Ball chips in a mill load contribute mass and therefore also contribute to mill power draw, ...

Effect of ball size and powder loading on the milling ... As the powder loading increases from 1 to 35 g at a given rotation speed and ball size, the milling ...

Improve the efficiency of the Clinker Grinding Ball Mill. First, the ball stone. Ball with stone size is very important, stone balls is better to have some small, so ...

Grinding and Milling Systems Course. ... * Ball mill grinding equations and dimensioning. ... * Grinding aids and other tools to boost efficiency.

ball mill grinding affect grinding efficiency . Request for Quotation. You can get the price list. This article needs additional citations for verifiion.

1. Introduction. Ball mills are the most common and versatile type of tumbling mill. They are remarkable in that they can operate over a very wide range of conditions ...

A ball mill generally loses its grinding efficiency remarkably at fine grinding. This is because fine particles from ground materials agglomerate and adhere to the ...

The optimal ball diameter in a mill 333 The grinding efficiency of the narrow particle size fractions with ball charge ...

THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 93 Graph 5. Pulp charge and ball charge .

Ball Mill. 140 likes. Ball mill for grinding various ores and other materials, are widely used in mineral processing, building materials and chemical...

The specific selection function effect on clinker grinding efficiency in a dry batch ball mill ... Keys words Cement clinker, Ball mill, Dry grinding, ...

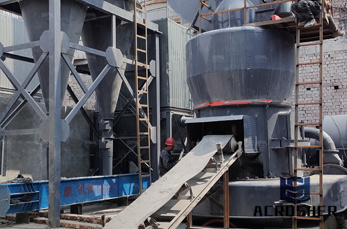

Hongke professional production and sales Ball Mill, Raymond Mill and other Grinding equipment, productsfavored by the majority of users.

Mill (grinding) Wikipedia, the free encyclopedia. Ball mill . A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder ...

A cement mill (or finish mill in ... The efficiency of the early stages of grinding in a ball mill is much greater than that for ... The energy efficiency of this ...

WhatsApp)

WhatsApp)