holderbank mill optimisation system

Utilizing waste heat from the kiln exhaust, clinker cooler hood, ... Optimization addresses the grinding process, maintenance and product quality.

WhatsApp)

WhatsApp)

Utilizing waste heat from the kiln exhaust, clinker cooler hood, ... Optimization addresses the grinding process, maintenance and product quality.

Hybrid simulation and energy market based optimization... 67 Wind Power Cement Plant Plant FRR Battery Fig. 2 Integration of wind power plant and battery

Radiotracer Investigation of Clinker Grinding Mills for ... optimization of such mills will be possible if the ... considerable amount of power. Grinding of the clinker

Coal Crusher Clinker Grinding Unit; ... Pulverizer Ball Mill Optimization. ... Pulverizing System Optimization of Thermal Power Plant. ...

Alternative Fuels Mixture in Cement Industry Kilns ... mixed in the phase of clinker grinding. ... Mixture in Cement Industry Kilns Employing Particle ...

Conventional Clinker Grinding – A New Approach to the Prediction . optimization, Modelling ABSTRACT The current (2004) . electrical power consumption in clinker ...

power stations for grinding the coal, ... grinding the clinker and at ceramic plants for grinding the ... optimization mode in search for an optimal loading of ...

PROCESS DESIGN OPTIMIZATION OF FUEL AND . PROCESS DESIGN OPTIMIZATION OF FUEL AND POWER CONSUMPTION IN CEMENT PLANT ... in the clinker grinding system because of ...

CEMENT GRINDING OPTIMISATION ... The cement clinker grinding circuit reduces the feed from 80% passing size between 10 ... According to Bond the specific power ...

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant ... grinding time and power input further to produce ultrafine particles, ...

Training Courses based on the Grinding Software ... Volume Load Power Kit ... 53. Energy Optimization Calculator

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' ... operational experiences from the first VRM for clinker grinding ... 50% less power than a ball mill when grinding ...

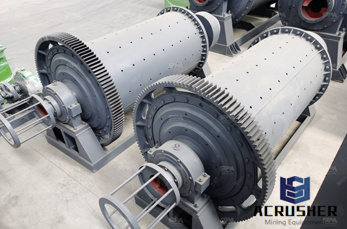

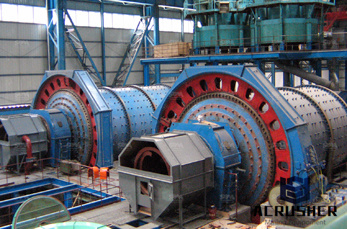

Multichamber cement mills,Clinker grinding ball mills ... Multichamber cement mills. For all dry grinding applications, cement production is certainly the most ...

cement clinker grinding plant india. ... Design and Optimization of Ball Mill for Clinker . ... The Cement Grinding OfficeMill power calculation.

PROCESS DESIGN OPTIMIZATION OF FUEL AND POWER CONSUMPTION IN CEMENT PLANT ... plant will benefit in the clinker .

optimization of the cement grinding process to achieve a ... grindability of clinker or changes in grinding aid ... Cement grinding is an extremely power ...

cement grinding optimization. ... There is potential to optimise conventional cement clinker grinding ... Impact on Specific Power Consumption and ... grinding ...

Objective of Ball mill optimization Mill performance test ... 7 . grinding system Clinker Gypsum ... Power consumption of mill went ...

Burning alternative fuels can lead to instability in the clinker ... Mill optimization Grinding makes up a ... Expected benefits of a process optimization ...

cement plant equipments manufacturer and suppliers of clinker . Clinker Grinding Units : ... the cement industry with respect to the optimization of fuel and power costs.

MULTIPLE WAYS OF ENERGY CONSERVATION COST REDUCTION IN CEMENT ... more efficient clinker grinding. Kiln optimization ... of fan power by kWh/t clinker .

Traditional clinker grinding station adopts ball mill to grind clinker, and has much dust, loud noise and high energy consumption in the process of production, it ...

Optimization Grinding ... Adaptive Control Optimization of Grinding ... optimization of clinker grinding power. Grinding trends in the cement industryCement Lime ...

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant. Sanjeev T. Patil. ... Appliion:Cement Plant, Clinker Grinding Unit, Thermal Power Plant.

WhatsApp)

WhatsApp)