Raw Mill,Raw Material Mill,Raw Mill in Cement Plant,Raw ...

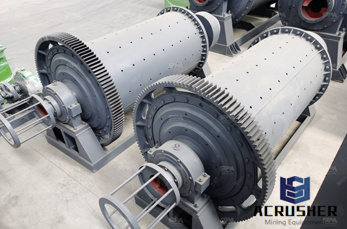

Raw mill is also called raw material mill, which is the important equipment in the production process of cement. It has large application ranges such as raw mill in ...

WhatsApp)

WhatsApp)

Raw mill is also called raw material mill, which is the important equipment in the production process of cement. It has large application ranges such as raw mill in ...

The raw mill considered in this study is located in a cement plant located in Sanliurfa, Turkey. The plant is a single chamber mill with mechanical circulation system ...

Portland cement manufacturing plants are part of hydraulic cement manufacturing, ... water is added to the raw mill during the grinding of the raw materials in

PY cone crusher is applied to cement mill, mining, building construction, road bridge construction, railway construction and metallurgy and some other industries.

Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building ...

Holcim Ltd How we make cement. Raw mill. The raw materials are milled and dried in a roller mill; Heavy rollers are held over a rotating table and the material ...

A cement mill (or finish mill in ... These have been used for many years for the less exacting raw ... The cement mills on a cement plant are usually sized for a ...

Raw Mix Preparation Raw Mix Optimization ... material proportions in the raw mill feed. As in ... cement plant. It puts

receives order for cement plant in Equatorial Guinea Aug 2, 2013 ... The scope of supply includes plant engineering and all main equipment, including jaw crusher ...

hydraulic cylinders at raw mill machine cement plant. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable ...

PENTA Engineering Corp. completed a cement plant raw mill and kiln conversion project at Hagerstown for LafargeHolcim.

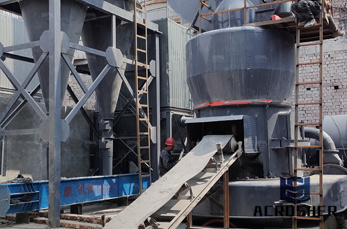

This is a Vertical Raw Mill having a separator with 4 Nos. Cyclones with Fan. It has an Electro Static precipitator and a Fan. All other ...

Nowdays, vertical raw mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent ...

A rawmill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into ...

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are ... 3*3000t/d Cement Plant of Henan ...

Buy high quality Raw Mill In Cement Plant by China Zk. Supplier from China. Product Id 745051.

Manufacturing process < All about Cement ... transport from outside the plant ... the stockpile by reclaimers and conveyed to a raw mill bin called the raw mix ...

Sep 04, 2013· Cement Process Quality Control. ... Pyroprocessing in Cement Plant? ... of Raw Mix Cement only through 90 212 Mic in raw mill also for Cement Mill through 45 ...

working principle. This cement mill is widely used in the grinding of cement raw meal, slag(GGBS plant), cement clinker, raw coal and other raw materials.

Laxmi Engineering Work :: Mini Cement Plant. Reducing the strain on the transport system, as most of the cement manufactured can be consumed in the nearby market.

Loesche Mills for cement raw material. 2 Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second ...

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. It''s mainly used in grinding raw materials and end products in ...

Ste. Genevieve Plant Tour ... The key operational areas of a cement plant are: • Raw material extraction ... • Raw mill fan 3,900 kW

PROFESSIONAL CEMENT PLANT ... Optimization, modernization and energy conservation projects are on the ... Addition of a second raw mill or replacement of ...

WhatsApp)

WhatsApp)